Full Strength, Speed, Reliability

Reinforcing bar preparation for Ancon CXL joints

Automatic quality control

Cutting

The end of each bar to be joined is cut square for even distribution of load while forging and for the correct performance of the coupler in the joint

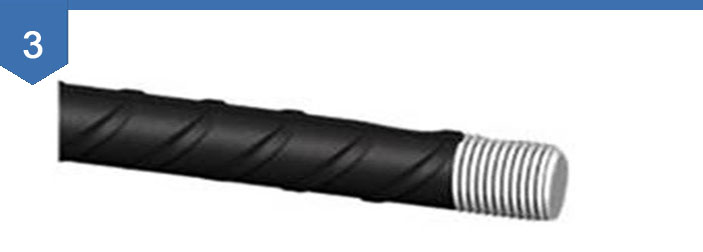

Cold Forging

The core diameter of the bar is enlarged by cold forging up to a certain value

Thread Cutting

Parallel metric right hand single threads are cut onto the enlarged ends.

Proof Loading

The threaded end is then proof tested to a force equal to the characteristic yield strength of the bar, which allows removing the internal stress of the threaded area

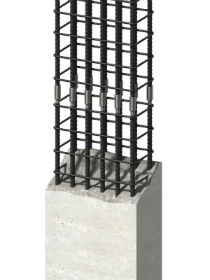

Types of Ancon CXL Couplers:

Standard Ancon CXL Couplers:

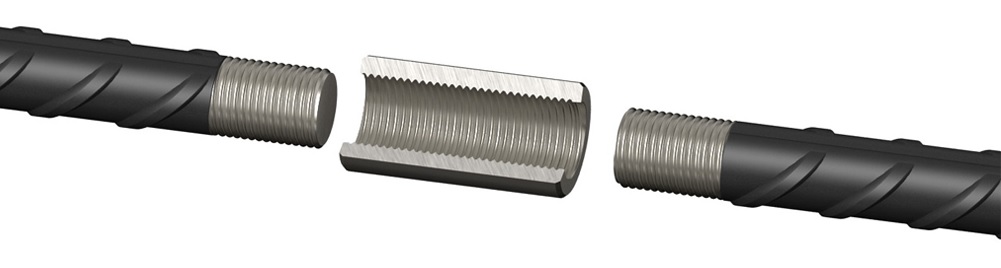

CXL Type A

The CXL Type A system is suitable for applications where the continuation bar can be rotated

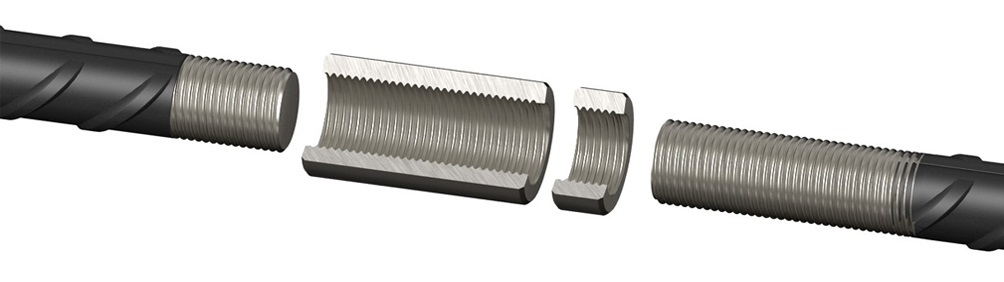

CXL Type B

The CXL Type B system is used for applications where it is difficult but not impossible to rotate the continuation bar

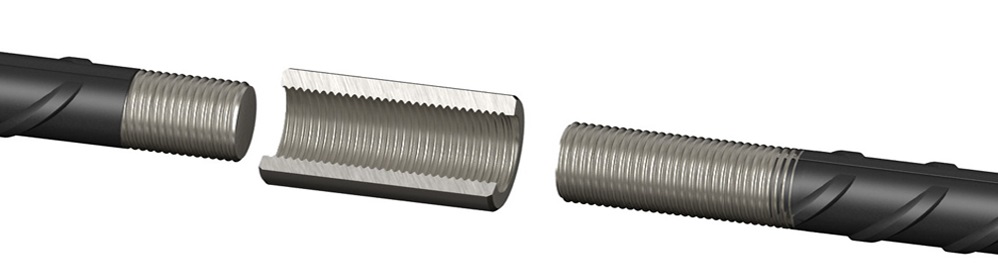

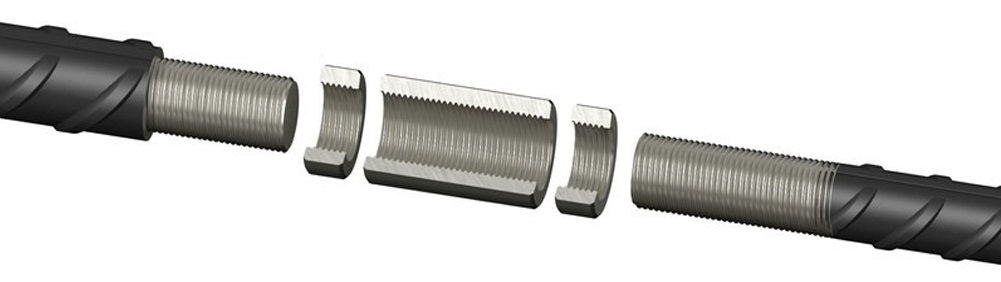

CXL Type C

The CXL Type C system is used where the continuation bar cannot be rotated

CXL Type D

The CXL Type C system is used for applications with high standards of fatigue and/or cyclic reliability characteristics of the joint

Transition CXL Couplers

The Ancon CXL Transition coupler is used to join reinforcing bars of different diameters where one coupler can be rotated

CXL Headed Anchor

CXL Headed Anchor can reduce congestion, simplifying bar placement

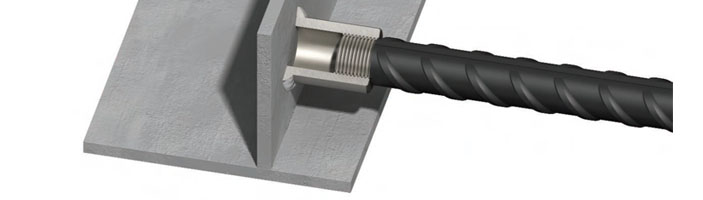

CXL Welded Couplers

CXL welded couplers provide a convenient means of connecting reinforcing bars to structural steel plates or sections.